|

泡麵加工製造設備:

|

Fully automated instant noodle production

equipment designed to produce instant noodles to pillow

type, cup/bowl type, combined and etc. Providing highly

efficient productivity, low oil usage characterizes the

equipment. Furthermore, various capacity and process

designs are available upon specific requirement.

|

|

Bag

type noodles Bag

type noodles

|

|

|

|

1. mixed water solution tank

2. hodling bin

3. dough mixer

4. round feeder

|

5. compound roller

6. continuous roller & slitter

7. 3 stage steamer

8. cut & folding machine

|

9. fryer

10. cushion conveyor

11. cooler

12. infeed device

|

|

|

Cup/Bowl

type noodles Cup/Bowl

type noodles

|

|

|

|

1. dough mixer

2. dough feeder

3. continuous roller

|

4. continuous roller & slitter

5. 3stage steamer

6. cutting machine

|

7. fryer

8. oil seperator

9. cooler

|

|

|

Japanese

style fresh boiled noodles Japanese

style fresh boiled noodles

|

|

|

|

1. vacuum mixer

2. dough feeding conveyor

3. compound roller

4. aging conveyor

5. continuous roller

|

6. 2 stage steamer

7. cooker

8. pouch packing machine

9. printer

10. check weigher

|

11. channelizer

12. sterilizer feeding system

13. .sterilizer & cooker

|

|

|

Other

noodle production systems Other

noodle production systems

|

|

|

點心加工製造設備:

|

Fully automated snack food processing machinery

designed to produce wide range of snacks complying

consumer's tastes. Providing highly efficient

productivity, low oil usage characterizes our equipment.

Flexible capacity and process designs are available upon

specific requirement.

|

|

Natural

potato chips Natural

potato chips

|

|

|

|

1. dumping machine

2. washing machine

3. peeling machine

4. inspection conveyor

|

5. slicer

6. washing conveyor

7. blancher

8. dewatering conveyor

|

9. fryer

10. ambient conveyor

11. seasoning equipment

|

|

|

Fabricated

potato chips Fabricated

potato chips

|

|

|

|

1. water service tank

2. oil service tank

3. high speed mixer

|

4. sheeting roller

5. brush roller

6. cutting roller

|

7. scrap bypass conveyor

8. fryer

9. ambient cooler

|

|

|

Cereal

bars Cereal

bars

|

|

|

|

1. hopper feeder with pedestal

2. incline conveyor

3. continuous mixer

4. sheet forming machine

|

5. gauge roller

6. additional spice-feeder

7. belt conveyor

8. cooling tunnel

|

9. ring cutter

10. spreading conveyor

11. guillotine cutter

|

|

|

Frying

/ Roasting Frying

/ Roasting

|

|

|

|

1. pellet feeder

4. packaging

|

2. switchable processing units

- (a). roaster

- (b). rotary wheel fryer

- (c). fluid bed dryer & roaster

- (d). continuous pellet fryer

|

3. seasoning feeder and tumbler

|

|

|

Pellet

extrusion and drying Pellet

extrusion and drying

|

|

|

|

1. screw conveyor

2. flour feeder

3. screw conveyor

|

4. ribbon mixer

5. forming & extruder

6. 1st dryer

|

7. 2nd dryer

|

|

|

Cold

extrusion Cold

extrusion

|

|

|

|

1. mixer

2. incline conveyor

3. cold extruder

|

4. fryer

5. ambient cooler

6. seasoning equipment

|

7. dryer

|

|

|

Cereal

Flaking Cereal

Flaking

|

|

|

|

1. extruder

|

2. pneumatic feederr

|

3. flaking mill

|

|

|

Corn

chip Corn

chip

|

|

|

|

1. extruder

4. cutting machine

|

2. pressing rolls

|

3. belt conveyor

|

|

|

Other

snack production systems Other

snack production systems

|

|

|

單一加工食品處理裝置:

|

Beside each part of complete snack & noodle

production lines, Special single units for specific

purposes such as general-purpose oil heater, laboratory

use or pilot production before deciding whether to

introduce it on a larger scale are available.

|

|

Oil

heater Oil

heater

|

|

Compact sized new arrival frying oil heater which is

characterized by an improved oil turnover rate with a

half of usual oil volume efficiently reduces fuel cost

and minimizes oil degradation while providing

user-friendly maintenance, better flavour and texture.

|

|

Sludge

fryer Sludge

fryer

|

|

Too dry sewage sludge using a fry-drying process

optaining high energy combustible product. While

condensing oily-vapor to inflammable oil, gas burns up

inside the fryer eliminating foul smell. It is

characterized by its best performance regardless of fuel

oil types.

|

|

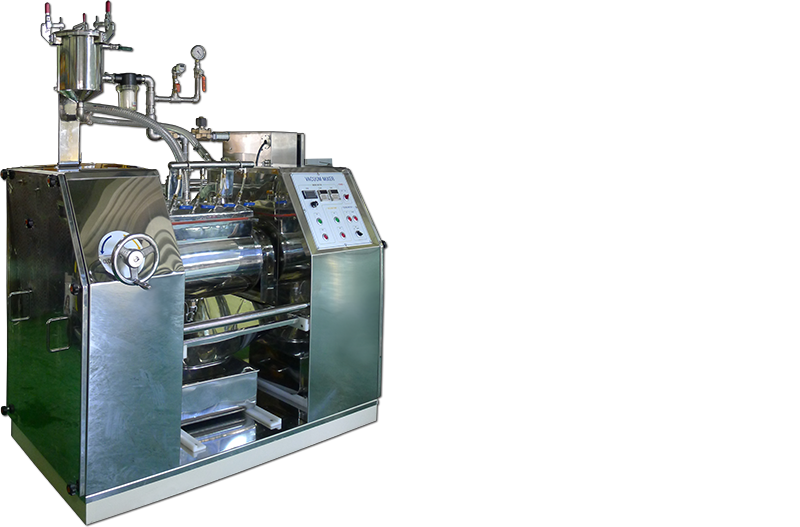

Vacuum

mixer Vacuum

mixer

|

|

When vacuum is applied, it removes oxygen and prevents

decomposition of sensitive ingredients or thwart

unwanted chemical reactions and microbial growth.

Minimizing oxygen content to maintain consistent high

quality during shelf life through reduced oxidation,

plus increased color uniformity and uniform rheology

increased product stability with consistency.

|

|

Vacuum

fryer Vacuum

fryer

|

|

With our vacuum fryer it is easier to maintain natural

colors and flavours of the finished product. Due to the

lower temperatures applied , the formation of suspected

carcinogen acrylamide is significantly lower than in

standard atmospheric fryers. The fat absorption of the

products is also reported to be lower than in

atmospheric fryers.

|

|